Company History

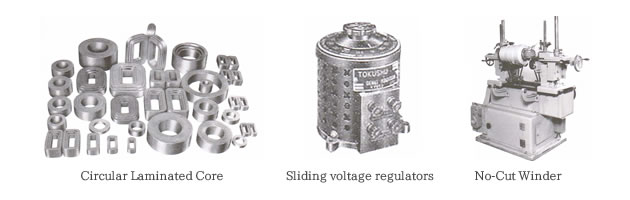

Establishment as the Special Electric Equipment Research Laboratory and development of Japan’s first circular laminated core

| 1939 | The Special Electrical Equipment Research Laboratory was established in Osaka. |

|---|---|

| 1943 | Development of Japan's first circular laminated core used in sliding voltage regulators. |

| 1945 | War damage forced a move to the current location (Yamashina-ku, Kyoto), where operations continued. |

| 1948 | Development of voltage regulators with coupled coils that used circular laminated cores; this laid the groundwork for becoming a manufacturer specializing in sliding voltage regulators. |

| 1951 | Corporate name was changed to Special Electrical Equipment Manufacturing Co., Ltd. |

| 1952 | Sliding voltage regulators were issued official authorization numbers. |

| 1955 | Development of cores with ductile coils as well as the No-Cut Winder. These developments helped revolutionize and expand the columnar transformer industry. |

Development and commercialization of Induction Heated Jacket Rolls

| 1960 | Development and commercialization of U-shaped core transformers and saturable reactors using split ductile wound cores. |

|---|---|

| 1961 | Corporate name changed to Special Electrical Equipment Co., Ltd. |

| 1964 | Development and commercialization of the world's first induction heated roll for synthetic fiber heat stretching machines. Development and commercialization of single- and three-phase butt reactors, transformers, saturable reactors and other induction heating devices. |

| 1969 | Development and commercialization of Induction Heated Jacket Rolls. |

| 1970 | Developed a triple-frequency power source for blast furnaces (1,500 kW Tripler) and licensed induction heating roll technology to Dienes Co., Ltd. in the former West Germany. |

From Special Electrical Equipment to TOKUDEN

| 1980 | Corporate name was changed to Tokuden Co., Ltd. Development and commercialization of a Jacket Roll capable of using three-phase power sources. |

|---|---|

| 1984 | Commmercialized four-meter wide rolls for nonwoven embossing calenders. This represented a serious push into the nonwoven fabrics market. Also developed and commercialized was the high-temperature (400℃) Jacket Rolls. |

| 1985 | Establishment of wholly-owned subsidiary Tokuden, Inc. in the United States. Development and commercialization of heat-reaction pots and Univestors by combining induction heating and Jacket Chambers technologies. |

| 1988 | Establishment of the Makino Plant. Received order for 160 high-temperature rolls (400°C) for carbon fiber production from a company in the United States. Development and commercialization of high-temperature (600℃) Induction Heated Rolls for steelmaking. |

Expansion of Makino Plant and reinforcement of production capacity

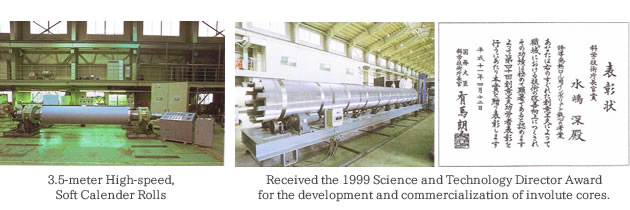

| 1993 | Expanded the Makino Plant and developed an integrated production system for large rolls. Delivered 3.5-meter high-speed, soft calender rolls to major paper manufacturers. Validated the effects of high-temperature calendering on paper. |

|---|---|

| 1994 | Development and commercialization of involute cores. |

| 1995 | Completed a large induction heated spin beam. |

| 1996 | Expanded facilities and strengthened the production system at the Makino Plant. |

| 1998 | Makino Plant awarded ISO9001 certification. Pilot Calender Machine completed. |

| 1999 | Received the 1999 Science and Technology Director Award for the development and commercialization of involute cores. |

Further research and development of Jacket Rolls

| 2000 | Delivered 7.6-meter wide rolls for paper processing to a Swedish paper manufacturer. |

|---|---|

| 2004 | Development of the Fluid Circulation Jacket Rolls which was awarded the 2003 Energy Conservation Grand Prize. |

| 2005 | Expanded the Makino Plant to include a third building. A state-of-the-art Technical Center was commissioned at the Makino Plant. |

| 2006 | Development and commercialization of the High-Precision Induction Heated Jacket Roll. Development of High-Temperature (700℃) Induction Heated Rolls. |

| 2007 | The Kyoto Plant, Makino Plant and Tokyo Business Office were awarded ISO14001 certification. |

| 2009 | Completion of sample evaluation and commercialization of high-pressure multi-layer transformer incorporating a multi-layer involute core. Development and commercialization of the Hybrid Rolls (Induction Heated Jacket Rolls with cooling function). |

Start of commercialization of Induction Heated Apparatus

| 2010 | Start of commercialization of Midfrequency Induction Heated Apparatus. |

|---|---|

| 2011 | Development of UPSS Superheated Steam Generator. |

| 2013 | Received the 2013 Oscar Certificate from the Advanced Scientific Technology & Management Research Institute of Kyoto. |

| 2014 | Received the 2014 Certificate from the Kyoto Genki-jirushi Medium-small Business Certificate Program. |